Manufacturing

-

Carefully cleaned, then opened to remove roe by specialists.

First we clean the outside of the sturgeon with electrolysed hypochlorite water and sterilise it carefully. It is then taken to the primary processing room, where laparotomy and roe removal are performed by specialists.

The removed roe is put in a pass box and transferred to the secondary processing room.

-

The roe is gently treated by hand.

The roe is protected by a membrane in the pass box. Keeping the roe temperature controlled with ice, the membrane is then carefully removed and the roe loosened.

-

Any impurities are removed.

In order to ripen roe over a long period of time using only salt and no preservatives, it is imperative to remove any impurities. The whole process is climate controlled to ensure the quality of the roe.

-

The key to the taste is a special blend of rock salt and perfect maturation.

We season lightly with a special blend of rock salt for long term ageing.Since the maturing process lasts several months, we regularly taste, using a unique method without ever opening the ageing containers.

The caviar sleeps deeply until it reaches its most delicious moment.

-

Arranging rather than just packing.

We manually and carefully place the caviar into each glass jar so that each grain is neatly arranged when you open the lid.

If any crushed grains are found, we remove it them one by one.

-

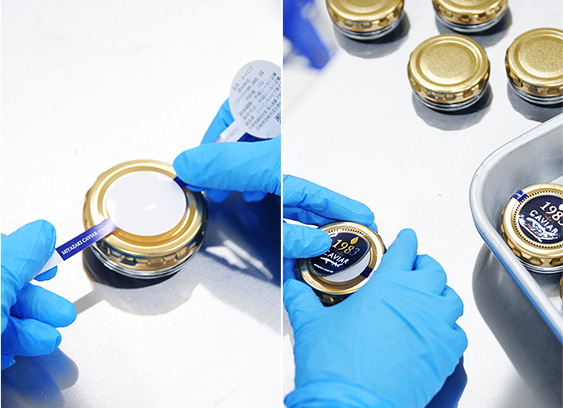

Packaging and labelling.

In accordance with the universal labelling system determined by CITES (Washington Convention), we seal the package with a tamper-resistant sticker and put a label indicating the country of origin, the sturgeon harvest year, the official registration code of the processing plant, lot number of the caviar, etc.

This tamper-proof seal cannot be reapplied once opened, so it's easy to tell at a glance if it has been opened before you receive it.* CITES's universal labelling system advises that no caviar should be imported without a tamper-proof seal.

-

Perfect traceability.

Our IoT-based system fully tracks the caviar by lot, 24 hours a day, 365 days a year. This means that all our caviar is perfectly traceable. We know when and from which sturgeon a specific roe was harvested.

-

Authentic matured caviar adds colour to your dining experience.

Only caviar that has passed the test of time can be called “Miyazaki Caviar 1983”.

One day we hope it will be said that “caviar is all about Japan”.

We continue our quest for the highest quality caviar.